Analyze The Difference Between Traditional Welding And Laser Welding! PURE-AIR Laser Fume Extraction System!

PURE-AIR Fume extraction system with LCD display, air flow can be adjustable, with filter block alarm function, small running noise, it can work in the office and at commercial envoirnment and industry.

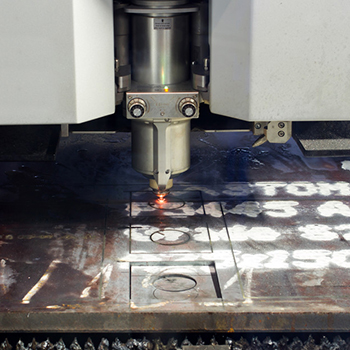

Compared with other welding technologies, the main advantages of laser

welding are:

1. Fast speed, large depth and small deformation, which can be adjusted

flexibly according to actual conditions.

2. It can be welded at room temperature or under special conditions, and

the welding equipment is simple. The laser passes through the electromagnetic

field, and the beam does not shift; the laser can be welded in vacuum, air and

certain gas environments, and can be welded through glass or materials that are

transparent to the beam. It has a wide range of applications and strong

anti-interference.

3. It can weld refractory materials, and can weld heterogeneous materials,

with good effect and various processing materials.

4. After the laser is focused, the power density is high, and the

processing is fine when welding high-power devices.

5. It can be used for micro welding. After the laser beam is focused, a

small spot can be obtained, and it can be accurately positioned. It can be used

in the assembly welding of micro and small workpieces produced by mass

automation, and precision processing is also possible. (The smallest spot can

reach 0.1mm)

6. The laser beam is easy to realize the beam splitting according to time

and space, and can perform multi-beam simultaneous processing and multi-station

processing, which provides conditions for more precise welding and multiple

options.

However, laser welding also has certain limitations:

1. It requires high accuracy in assembly of weldments, and requires that

the position of the beam on the workpiece cannot be significantly shifted. This

is because after the laser is focused, the spot size is small and the weld is

narrow, which is filled with metal materials. If the assembly accuracy of the

workpiece or the positioning accuracy of the beam does not meet the

requirements, it is easy to cause welding defects, and the original material

requirements are high.

2. The cost of the laser and its related systems is relatively high, the

one-time investment is relatively large, and the price of equipment replacement

is high in the later period.

PURE-AIR is a research and development and manufacturer of workshop smoke

and dust purification equipment for laser processing companies. Its products

include laser smoke filters and other purification equipment. As a laser smoke

filter manufacturer PURE-AIR has always maintained long-term cooperation with

laser manufacturers.

If you want to buy fume extractor, please contact”DongGuan PURE-AIR Tech

Co,Ltd.”E-mail: sales01@pure-airtech.com