In the process of PCB electronic industry processing and production, a ubiquitous solder waste gas will be generated. The tin wire will contain flux, which will burn and decompose to generate carbon dioxide, sulfur dioxide and other waste gas components during the soldering process, and these exhaust gas contains A lot of harmful substances. At this time, a PURE-AIR high quality laser engraver fume extractor is needed.

What should manufacturers pay attention to?

If these waste gases are not treated in time, when harmful substances are floating in the air, they will not only pollute the surrounding environment but also endanger human health. Especially those who work in the PCB electronics industry, if they breathe this type of gas for a long time, it will have a great impact on the body of the staff and cause various respiratory diseases. Therefore, it must be treated before it can be discharged into the atmosphere.

So how do manufacturers control the soldering waste gas?

At present, the conventional technical methods of high quality gas filter on the market mainly have the following three aspects:

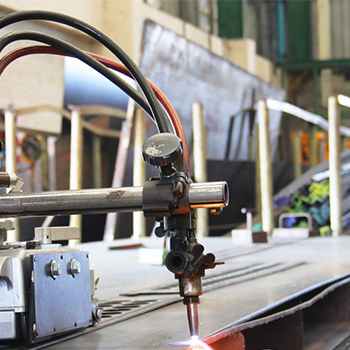

Filtration adsorption type smoke purification: filter adsorption type high quality laser fume extractor can use organic polymer composite fabric or felt with high oil absorption performance, inorganic filter material (hydrophobic perlite, ceramsite, coke, etc., used alone or in combination) , The filter material can be placed in a direction perpendicular or parallel to the flow direction of the flue gas, and the purification efficiency needs to be more than 95%.

Electrostatic dust purification: The electrostatic deposition method is to introduce the smoke purifier into a high-voltage electric field, so that the particles in the oil fume and fire smoke are charged, and under the action of the electric field, they move to the dust collector and deposit them. The purification efficiency is usually over 85%, which is costly and unsafe.

Low-temperature plasma method: The principle is to use the high-voltage electrostatic method at the same time, set a plasma field at the front end of the electrostatic field, and use the large amount of free radicals excited by its high energy to degrade the oil fume particles and reduce the viscosity; in the plasma generation process In the medium, the instantaneous high energy generated by high-frequency discharge can open the chemical bonds of some harmful gases and decompose them into elemental atoms or harmless molecules. This technology is currently the most advanced oil fume and fire fume treatment technology on the market, with a high removal rate (less than 90%), the treated gas has no peculiar smell, and it is convenient to maintain, but the equipment investment is very high.

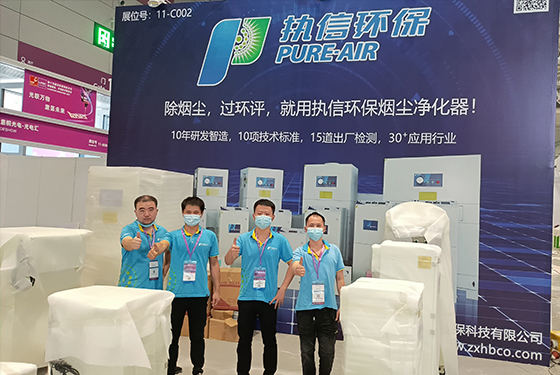

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.