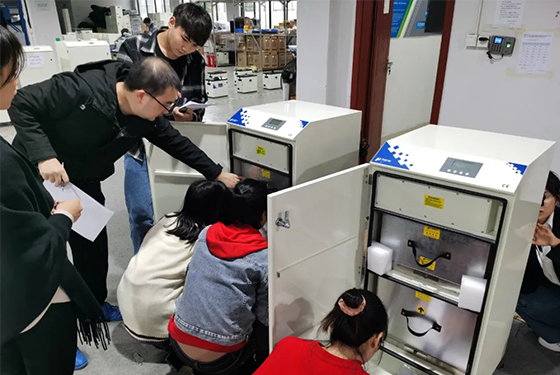

As a very important step in the production and processing procedure, the

grinding and polishing of the enterprise is widely used in the application of

steel casting, various metal welding, and various metal material machining

processes. It is an indispensable processing part for many domestic and foreign

production and processing enterprises. ring. Pure-Air professional dust

collector manufacture with 10years industry experience.

During the grinding process, a large amount of dust (abrasives of the

grinding wheel, fibers and particles of the cloth wheel with a shaft), metal

shavings (carbon steel, stainless steel, lead, copper) and other harmful

substances and harsh noise will be generated, because the ordinary grinding room

does not have dust removal Noise reduction function, in order to reduce the

pollution of the grinding operation to the production environment, many

companies have adopted different methods, but the effect is not satisfactory.

For the analysis combination of noise reduction and dust removal principles, a

grinding and polishing dust collector is used to solve the above two

problems.

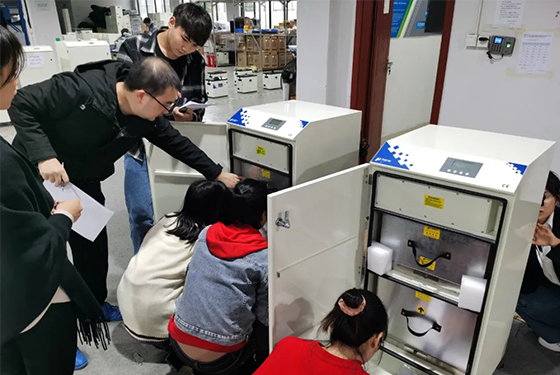

The Polishing dust collector adopts a reciprocating operation mode in the

lower pump and the upper row. The design principle of machinery and equipment is

to allow workers engaged in grinding and polishing to consider many processing

aspects such as working environment, equipment operation reliability, operation

and maintenance convenience, etc., on the premise of meeting the technological

requirements of production and processing, and effectively improve the smoke and

dust pollution environment in the workshop.

The smoke and dust pollution in the workshop includes dust and gas entering

the polishing cabinet from the air inlet, first passing through the spoiler, the

dust-containing gas is evenly dispersed around the filter element, and the dust

is adsorbed on the outer surface of the filter element. The purified gas is

discharged through the filter cartridge through the air outlet on the upper part

of the box. As the use time increases, the dust absorbed by the filter element

gradually increases, and the resistance of the dust collector continues to

increase. In order to ensure a good dust collection effect, the resistance of

the filter element of the grinding dust collector must be controlled within a

limited range, and the pulse controller sends a signal to open the cycle.

With

pulse valve, compressed air is sprayed from the nozzles of the blowing pipe to

the corresponding filter cartridge. The gas in the filter cartridge instantly

expands, causing the dust collected on the outer wall of the filter cartridge to

fall into the dust box. Dust collector adopts a push-pull drawer structure, the

machine cleaning process is convenient and easy to master. The upper part is

equipped with a dust unloading board to ensure that the smoke and dust pollution

is absorbed into the grind and polishing dust collector.

If you want to buy dust collector, please contact with ‘Dongguan Pure-Air

Tech Co.,Ltd.’.