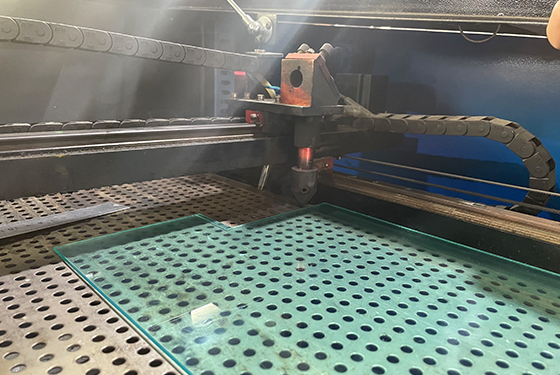

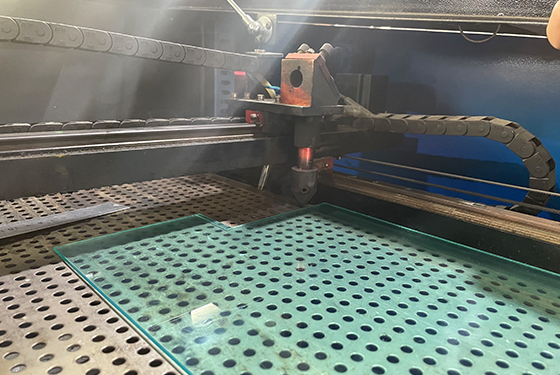

Mobile welding fume removal equipment, fiber laser marking dust collector is mainly used to remove dust in welding and cutting. These processes involve high temperatures, and there is usually an open flame on site. If the purifier is directly exposed to fire, some equipment parts may be damaged. Of course, sporadic sparks will inevitably be generated during the vacuuming process. Many welding fume purification equipment are also equipped with fire-proof nets and use new nano flame-retardant filter elements, which have good air permeability and are easy to remove dust. They are not afraid of fires and have a longer life than traditional filter materials. long. But pay attention to the action of the open flame during use, try to avoid direct contact with the dust removal equipment, and reduce unnecessary equipment wear.

1. Use flux-cored welding wire or oil-based welding parts on the surface of welding parts.

Flux-cored wire and welding parts with oil on the surface contain a lot of oil mist in the fumes generated during the welding process. These oil mists have high viscosity and adhere to the surface of the filter element. The filter is difficult to remove the dust removal device. This will accelerate the clogging of the filter element, causing the wind to drop sharply, or even completely block the filter element, thereby losing the filtering effect.

2. Deliberately extend the replacement cycle of the filter element.

In order to save investment in environmental protection dust removal equipment, even if the filter cartridge of the fiber laser fume extractor of the mobile welding fume extractor reaches a saturated state or is completely clogged, many factories do not consider replacing the filter cartridge. It is not recommended to deliberately extend the service life of the filter element, because when the filter element reaches saturation, the dust removal efficiency will definitely decrease, which will affect the dust removal effect and expose the enterprise to the risk of not meeting the environmental assessment standards.

Therefore, the filter element needs to be replaced regularly. The replacement time depends on the environmental conditions and the quality of the filter material. The filter element of the company's welding smoke purifier uses a new type of nanofiber material with surface adhesion. The soot filtration efficiency of the filter membrane is 99%, and it is equipped with a pulse cleaning system that can automatically clean the dust. The life of the filter cartridge can reach 6000 hours.

3. Control of running time.

After installation, the welding fume purifier can not be used randomly, and it has certain operating specifications. First of all, it is necessary to control the running time of the equipment. Under normal circumstances, after 8 hours of accumulated work, the equipment needs to be shut down for dust removal. Of course, if the equipment is equipped with a pulse back-blowing dust removal system, there is no need to stop the machine, just press the blowing button to start automatic dust removal.

Only the correct use of fume extractor co2 laser can avoid the above misunderstanding. On the basis of ensuring the dust removal effect, try to save economic costs. We hope that every factory will value it.

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.