Pure-Air,professional fume extractor& dust collector factory with 10 years industry experience.

According to the method of adding coating materials, laser cladding can be

divided into preset type and synchronous type. The preset type is to pre-place

the material to be coated on the surface of the base alloy by spraying or

bonding, and then irradiate it with a laser beam; the synchronous type is to

spray the coating powder directly into the alloy molten pool irradiated by the

laser. forming. The former is simple to operate, but has higher requirements on

the thickness of the pre-coated powder and the binder. The latter has high

production efficiency and good quality of the cladding layer, but has higher

requirements for powder feeding equipment and powder.

Laser cladding is a metallurgical process related to many aspects of

physics, chemistry, and materials science. Its ultimate goal is to realize the

interaction between laser and powder materials. There are many factors that

affect the quality of the laser cladding layer, and the cladding material is a

major factor. Since the birth of cladding technology, the choice of cladding

materials has always been valued by researchers. When designing, in addition to

considering the performance of the coating material, it is also necessary to

consider whether the coating material and the substrate have good compatibility

and matching. One of the important reasons for cracks in the laser cladding

layer is the difference in thermal expansion coefficient between the cladding

alloy and the substrate. To prevent the coating from cracking and peeling off,

the thermal expansion coefficient of the coating and the substrate should be as

close as possible. The smaller the difference, the less sensitive the cladding

layer is to cracking.

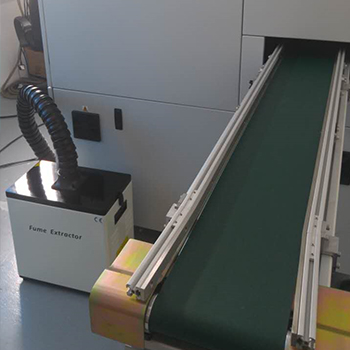

Therefore, technological innovation is the normal state of development in

the laser industry. Pure-Air laser cladding fume extractor have always maintained

a high density in cooperation with these laser processing companies to provide

more energy-saving, environmentally friendly, and highly efficient laser smoke

filter.

If you want to buy dust collector, please contact with ‘Dongguan Pure-Air Tech

Co.,Ltd.’.