Iron and steel smelting is an important pillar industry of my country's manufacturing industry. It has high requirements for steel production technology

and has many and complicated production processes. In the complicated production

processes, a large amount of dust and smoke will be generated.

1. A brief and detailed introduction of part of the process

The key of the steelmaking plant is composed of six parts: the blast

furnace itself, the feeding system software, the exhaust system software, the

liquefied gas purification equipment, the slag iron solution system software,

and the gas generator material system software.

The key production process is: iron raw materials and coke are entered into

the elevated road hopper of the steelmaking plant according to the belt

conveyor. After screening by vibrating screen, the iron element raw material is

sieved into particles above 5 mm, and coke is particles above 20 mm, and then

the raw materials are sent to the tank located in the blast furnace rotary kiln

according to the loading car. Enter the blast furnace. The blower motor sends

the cold air into the hot air boiler according to the cold air pipeline, and it

is heated to 1000~1200℃, and then blown into the blast furnace from the 14 air

outlets of the blast furnace body through the warm air pipeline. The warm air

moves inwardly in the blast furnace, and the original material goes down in the

blast furnace. The warm air heats the coke and ignites it, so that the iron raw

material is melted and restored under the heat effect, and the copper and carbon

elements are produced The oxidation reaction restores iron and slag. The molten

steel and slag are discharged according to the taphole, and the molten steel is

immediately sent to the ironmaking plant for application by the molten steel

truck, and the slag is converted into steel slag and sent to the slag powder

plant for application according to the slag flushing ditch.

2. Assessment of working conditions that cause smoke and dust

In the pulverizing system software, the blanking, vibration, and screening

of the pulverized coal will cause the pulverized coal to float and overflow

during the entire process of vibrating, sieving, and transportation. The

accumulation of pulverized coal in the transmission belt and the surrounding

environment will cause the following harm:

(1) When the pulverized coal is accumulated in the surrounding environment

of the transmission belt, the temperature of the pulverized coal will rise

slowly due to the heat generated by the slow oxidation of the pulverized coal,

and the rise of the pulverized coal will aggravate the further air oxidation of

the pulverized coal, and finally achieve the ignition point of the coal , It

will cause the pulverized coal to catch fire. In addition, when the pulverized

coal and gaseous compounds are in contact with the fire under a certain

standard, there is a high possibility of explosion safety hazards.

(2)The coal powder falls into the air and the workers breathe it into the

body during construction, which will cause certain harm to their health.

(3) The pulverized coal deposits on the transmission belt, which is very

easy to cause friction with the belt idler, resulting in an increase in the cost

of the belt idler and reducing the cycle time of the belt idler replacement.

3. Overview of the smoke and dust solution plan

Regarding the above situation, for the vibrating, grinding, screening, and

transportation of coal powder in the pulverizing system software of the

steelmaking plant, the drive belt head and tail wheel are equipped with

explosion-proof dust removal equipment, and the computer host is equipped with

antistatic filter cartridges. Fans, explosion-proof solenoid valves, explosion

vents, explosion-proof lamps, explosion-proof temperature sensors, etc. are used

to solve ash removal. Seamless steel pipes are used for dust extraction. The

tail is solved according to antistatic plastic hoses, which is convenient for

driving the tail wheel. Disassembly, assembly and maintenance of the motor and

the buffer roller.

In the vibrating screen blanking process, the closed space ventilation

solution is carried out according to the production of the vibrating screen

room. In addition, the design of repairing doors and windows allows employees to

observe the vibrating screen on the spot. Once there is a blockage, it can be

shut down and cleared immediately.

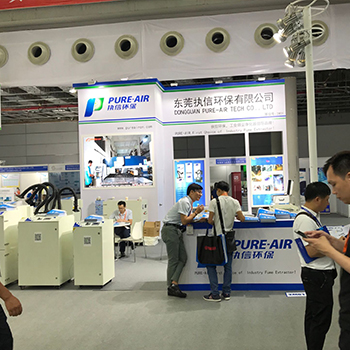

In response to the above problems,Pure-Air has developed a new series of

explosion-proof dust collectors, which are small in size, high in filtration

efficiency, and can meet explosion-proof requirements, and can effectively solve

the dust removal requirements of customers' conveyor lines.

If you want to buy vacume cleaner,please contact “Dongguan Pure-Air Tech ,Co,Ltd”