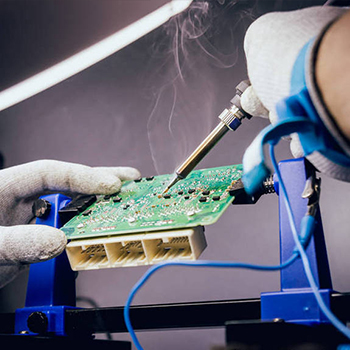

Smoke and dust purifiers, small dust collectors, laser cutting machine for sale, and other professional dust collection equipment, quality assurance has 10 years of supply experience in the industry, fast delivery speed, good after-sales service and many other advantages!

Three things to pay attention to when choosing a dust purifier and a small dust collector:

1. The use time can be fully matched with the working time, but the equipment needs to be cleaned on time:

Fume purifiers and dust collectors can be delivered to use after installation, but in order to ensure that the welding fume purifier maintains a stable air intake during the entire application process, it is necessary to turn off the equipment and clean the dust on time. If the equipment is equipped with the pulse dust removal system software, there is no need to shut down, just turn on the single pulse dust removal method during application. If the welding fume purifier is required to operate continuously, it is recommended to use equipment equipped with single-pulse ash cleaning system software. Its powerful automatic cleaning effect does not harm the work progress.

2. Choose suitable fume purifier, small dust collector, laser cutting machine fume filter:

The production workshop is generally divided into one station or multiple stations. If it is a single station or the total number of stations is less than 10, it is more suitable to choose a mobile welding fume purifier. For factories, it is more suitable to apply central dust removal system software, which can collect dust from the smoke and dust of a separate website and solve it in a unified way, which is more efficient and more efficient! In addition, it can also apply a fully automatic circulatory system welding fume purifier, which can not only complete multi-station, large-scale fume treatment, but also has a short installation cycle time. It occupies a small area and does not endanger all normal industrial plant manufacturing.

3. Ensure that the discharge concentration value can be qualified:

The most basic requirement for ash removal in processing plants is that the concentration of air pollutants after the solution is reduced to below the relevant specifications. Therefore, before applying welding fume purification equipment, it is necessary to understand the high efficiency of the purification treatment of the equipment to ensure that the discharge meets the regulations. In the continuous improvement of equipment manufacturing and quality inspection work, it is everyone's responsibility and obligation to ensure that each smoke dust purifier, small dust collector, laser cutting/engraving filter, and the quality of the original factory are guaranteed.

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd,

E-mail: sales@pure-airtech.com