|

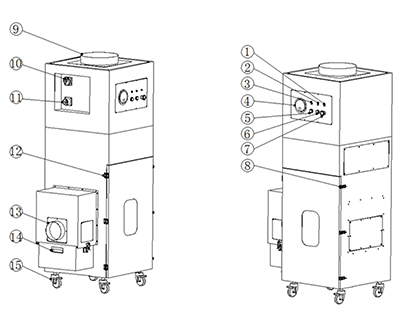

(1). Special structure design, small volume, low operating noise, and movable;

(2). Using special aluminum alloy impeller and Siemens Three phase motor, perfect combination of negative pressure and flow; stable operation, low failure rate, continuous operation;

(3). Set the main power switch, the electric control element adopts thermal overload protection, phase loss and phase sequence protection, high safety, and can realize remote control and linkage control functions;

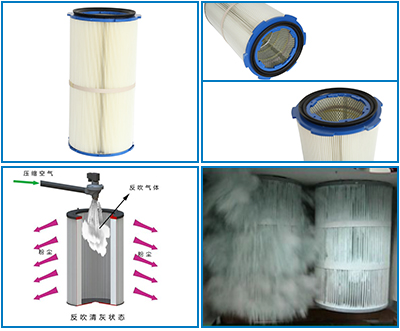

(4). Japanese Toray high-efficiency membrane filter cartridge is standard configuration, and the dust filtration efficiency is up to 99.7%@0.3 microns (note: our company's self-test);

(5). A fire-stop device is installed at the Inlet to prevent direct contact between sparks and the filter cartridge and damage the filter cartridge;

(6). A manual dust removal door is set to clean the dust inside the machine to prevent dust leakage;

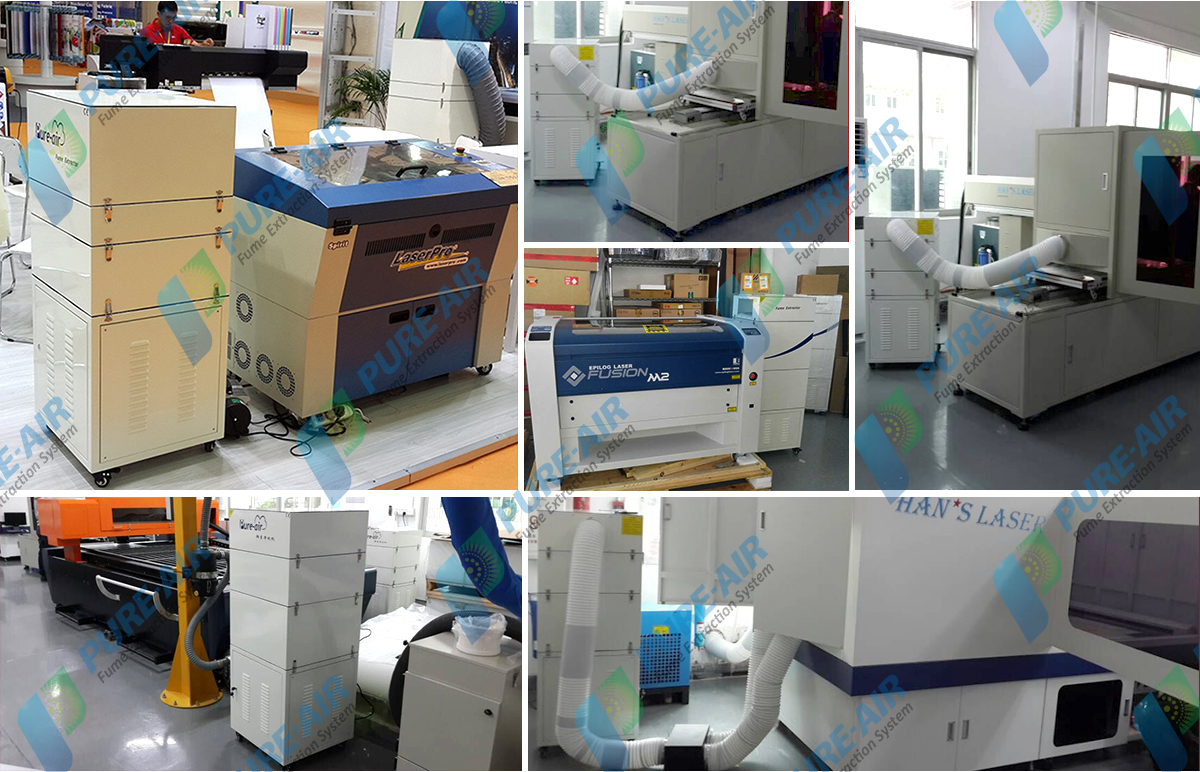

(7). The universal joint suction arm can hover at any position at 360 degrees. The Smoking hood adopts a large-caliber design to inhale smoke and dust with maximum efficiency; the Smoking arm hose is made of polyester, which is fire-resistant and flame-retardant.

|