|

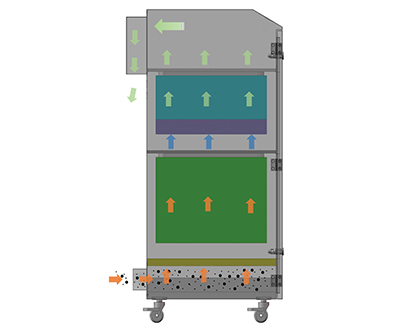

(1). The body is small in size, low in running noise, and equipped with casters for easy movement;

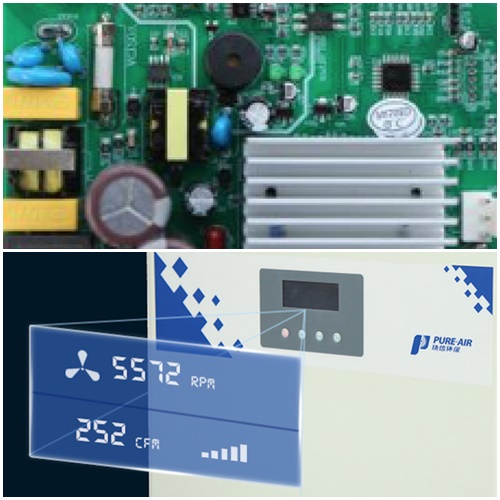

(2). TS-IQ, TD-IQ, FS-IQ series are equipped with low power consumption, maintenance-free, high-volume brushless fans, stable operation and long service life. The TS-LD-HP-IQ series is equipped with a high negative pressure brushless fan with large suction power;

(3). The air volume can be adjusted, and the LCD display can check the air volume and gear of the machine;

(4). The control system has a filter element blockage alarm function, prompting to replace the filter element in time;

(5). Configure wireless remote control to facilitate remote operation of the machine. The remote linkage start-stop interface can also be configured;

(6). Multi-stage large-capacity filter to ensure efficient purification of smoke, odor and harmful gases. It can be equipped with a special filter element to purify the smoke and harmful gases generated by PVC materials;

(7). The filtration efficiency of smoke and dust is as high as 99.7%@0.3 microns (our company's self-test), which can be discharged indoors;

(8). The filter element can be replaced separately, which reduces the use cost of the filter element and makes it easier to maintain and replace the filter element;

(9). Stainless steel chassis can be customized according to customer requirements.

(10)With castors, easily to move.

|