CHOOSE PURE-AIR SOLDERING FUME EXTRACTOR

Both traditional soldering and laser soldering need to solve the problem of

harmful gases and smoke in the soldering workshop, and implement environmental

protection and solder fume filters.

1. Adaptation differences to the requirements of the welding position of

the workpiece

In the application of laser soldering machine, it is found that when

welding some workpieces with more complicated surfaces, the traditional

soldering machine will easily interfere with the components on the surface of

the workpiece due to the large space occupied by the soldering iron tip and wire

feeding device. However, laser soldering can use spot solder paste or wire

feeding device, with laser non-contact heating characteristics, which takes up

less space and is less prone to interference than traditional soldering

machines. Therefore, laser soldering machines are more adaptable to the

worktable of the workpiece. .

2. Differences in the impact on the performance of soldering components

The traditional soldering machine heats the entire board when welding the

solder joints, that is, if you want to make the soldering position reach the

temperature required for welding, you must continue to heat the solder joints.

This will not only take a long time, but also cause the entire board to heat up

together. However, there will be some heat-sensitive elements on some

workpieces. When the temperature of the workpiece reaches a certain height, it

will affect the performance of this kind of heat-sensitive parts, which is

absolutely not allowed in terms of product performance. Compared with

traditional soldering machines, laser soldering is locally heated, which has the

advantages of short heating time, fast heating speed, and less impact on the

properties of surrounding devices. During laser soldering, the laser only heats

the part irradiated by the spot, and the local temperature The rapid rise can

quickly make the solder joints reach the required temperature for welding.

Because the temperature rises quickly and the time is short, the temperature

rise in the area around the solder joints is limited, so the heat impact on

other components is small.

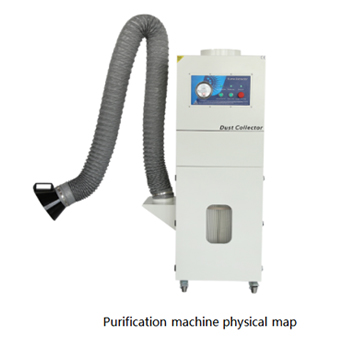

Pure-Air factory is committed to purifying harmful gases and smoke in

soldering workshops, and is a professional equipment manufacturer for

high-efficiency production and processing of enterprises. The solder fume

extractor is the object of choice for many soldering companies.

If you want to buy laser marking smoke purification, please contact ’Dongguan Pure-Air Tech Co.,Ltd.’.