Nowadays, many laser processing companies increase their own processing laser equipment with a lot of power. For laser cutting equipment up to tens of thousands of W, they need to support large-scale laser fume air filters.

The processing characteristics of large-scale laser cutting equipment are different from those of small-scale laser cutting machines, and they are suitable for different industries. This is caused by. Generally speaking, the power of large-scale laser cutting equipment will be higher, and it is used in industries that need to process large-scale mechanical products.

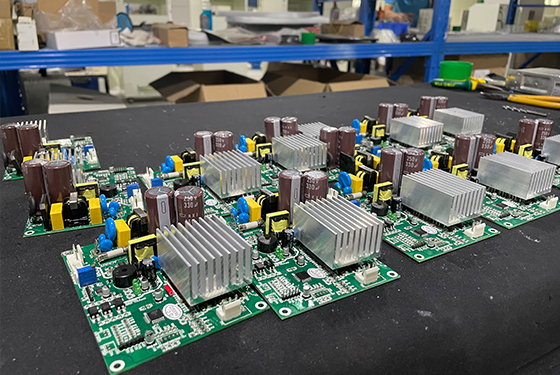

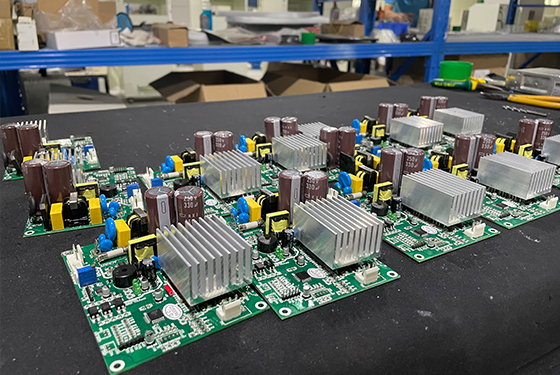

Processing characteristics of large-scale laser cutting equipment: It is a machine that integrates laser cutting technology, numerical control technology, and precision machinery technology. It uses advanced technology to bring better product processing. In terms of efficiency and quality, few products can Transcendence; large-scale laser fume and filtration

Because the processing method is more flexible, it can cut different types of profiles without damaging the surface of the material during cutting, so there is less mechanical deformation, which is more in line with the requirements of today's sheet metal workpieces; large laser cutting equipment has a higher cutting thickness, for example, low-power lasers The maximum cutting thickness of the cutting function may be 20mm, and the thickness of the large-scale high-power laser cutting function is limited to 40mm. Not only that, this is also the main reason for the difference between the two application industries. laser fume collector

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.