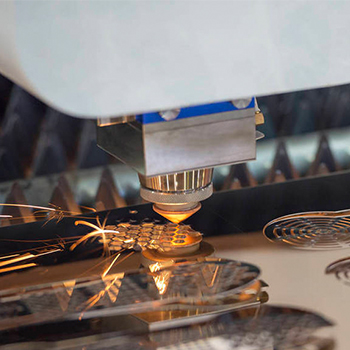

lathe work fume extractor, welding fume purification equipment is used to remove dust in welding and laser cutting. This whole process involves high temperature, and generally there is fire on the spot. If the oil fume purifier is exposed to the fire immediately, it is likely to destroy some machinery and equipment parts. Naturally, sporadic flames are unavoidable during the whole process of vacuum packaging. Many welding fume and oil fume purifiers are also equipped with fire safety nets, and new nano-technology flame-retardant filter elements are applied. They have good air permeability and are very easy to remove dust. They can deal with fire accidents. Don't be afraid, the service life is longer than traditional filter materials.

1. Use flux-cored welding wire to weld the component on the surface of the welding component.

Welding wire and welding components contain a lot of welding fume in the thick smoke during the whole welding process. This welding fume has high viscosity and adheres to the surface of the filter element. The filter device is difficult to remove dust pollution. This will speed up the blocking of the filter components, causing the wind to drop sharply, and even completely block the filter components, thereby losing the actual effect of the filter.

2. Intentionally increase the cycle time of filter element removal and replacement.

In order to better save the investment in environmental protection and dust removal equipment, even if the filter cartridge of the low noise fume extractor and welding fume purification equipment is completely blocked, many processing plants do not consider replacing the filter cartridge. Intentionally increasing the service life of the filter element, because when the filter element achieves contrast, the high efficiency of dust removal will definitely be reduced, which will harm the actual effect of dust removal and cause the company to encounter the risk of not complying with the environmental assessment specifications.

3. Manipulation of operating time.

Laser welding fume filter, welding fume purification equipment can not be abused after installation, it has certain operating standards. First, the operating time of the system must be controlled. Under all normal conditions, after 8 hours of accumulated work, machinery and equipment must be turned off to carry out ash removal. Naturally, if the machine equipment is equipped with a pulse anti-blowing dust removal system, it can automatically remove dust without shutting down.

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.