PURE-AIR FACTORY HELP GRINDING WORKSHOP

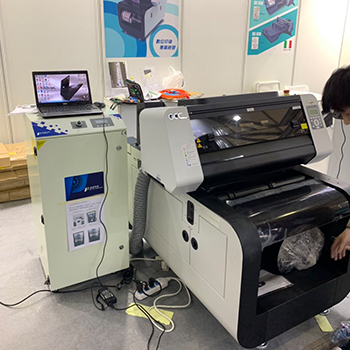

We have accumulated more than 10 years of experience in R&D, design, production, installation, commissioning and operation in Dongguan Pure-Air factory, a manufacturer of grinder dust collectors. Pure-Air factory has worked hard to research and carefully design the dust removal program. Among them, we have comprehensively considered and compared the performance characteristics of the vacuum cleaner for grinding dust to ensure that the dust collectors can work long-term and stably under various environmental conditions, reflect the cost performance, and enable corporate customers to reduce costs and other expenses when investing and using them.

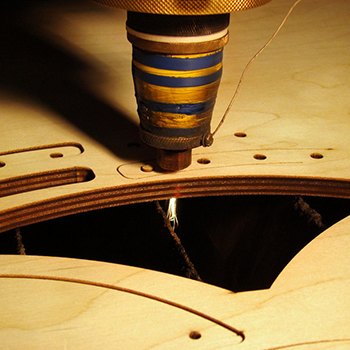

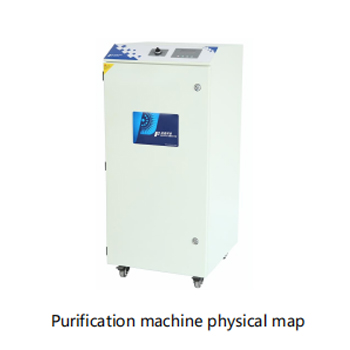

When the dust-containing gas enters the ash hopper through the filter bag from the air inlet, the dust and gas are separated, the dust is blocked on the outer surface of the cloth bag, and the clean gas enters the upper box through the filter bag, and then passes through the upper outlet of the upper box and is discharged by the fan .Dust accumulates on the inner surface of the filter bag and thickens continuously, which makes the resistance of the dust collector continue to rise. When the time relay of the control cabinet gives a dust-cleaning signal, the pulse valve starts the electromagnetic pulse valve row by row according to the pre-set program. After the pulse valve receives the signal, it instantly releases the compressed air and ejects the surrounding air to form a strong airflow to the bag. Reverse dust cleaning is performed to remove the dust attached to the outer surface of the filter bag. The dust sinks into the ash hopper silo under the action of gravity and is discharged by the ash discharge valve. After the dust removal, the filter bag enters the filtering state again

1. The operation is simple and easy to clean the dust. It has small size, high efficiency, low consumption, and can be moved flexibly.

2. Small footprint and large filtering area; each dust collector can be connected to 1 to 10 processing machines for dust removal and purification.

3. It can be applied to the central woodworking dust removal system with low production cost and energy saving.

The above is Dongguan Pure-Air Co., Ltd., in the field of polishing and polishing dust purification equipment, grinder dust collectors and polishing fume extractor. In addition, Pure-Air factory has also developed more than 100 types of smoke and dust purification equipment in more than 30 fields.