The safe production of flammable metal dust workplaces in enterprises not only requires Aluminum powder explosion-proof dust collector, but also requires more safety knowledge:

Do not install in dangerous buildings or illegal buildings: the production site has more than 2 safety exits to the outdoors, open evacuation doors, and ensure unobstructed passage: no anti-theft windows can be installed on floors above 2 (including 2 floors): factory buildings with flammable dust, It should be installed in a relatively independent single-story building. The roof adopts a lightweight structure. The multi-story building is a frame structure. The wall should have more doors and windows. The working area is not less than 30 square meters. Two pairs of doors and windows: 30 square meters or more, 50 square meters or less 3 pairs of doors and windows.

Use aluminum powder Explosion-proof dust collector for dust removal, and install relatively independent ventilation and dust removal devices and dust removal facilities (bag dust collector or wet dust removal device is recommended). The dust collector is installed in the exposed part of the building, at a height of more than 6 meters from the open flame, and the recovered dust is stored in a separate place.

The production workshop is cleaned daily, and the dust removal device is cleaned in time according to the amount of dust to minimize the dust accumulation in the workshop. It is strictly forbidden to use compressed air to clean. When cleaning, stop sanding and other dust-generating work.

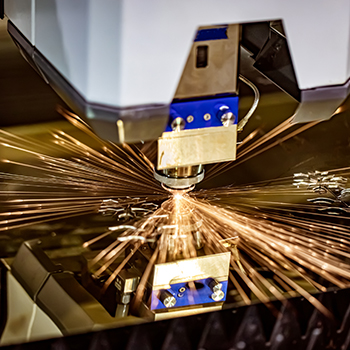

All open flames are forbidden in places where there is a danger of dust explosion. When conducting open fire operations in dangerous places such as dust and explosions, conduct hot fire inspections, stop polishing operations, and take corresponding protective measures. Use aluminum powder explosion-proof dust collector to check, and do not hit metal parts.

According to operating conditions and environment, equipped with fire-fighting equipment and personal protective equipment. There is 1 cubic meter of fire-fighting sand in the combustion of combustible dust, and fire-fighting sand must be used to extinguish the fire. To extinguish fires, prevent dust from rising and forming dust clouds. It is prohibited to use ordinary fire extinguishers to extinguish fires.

The circuit boards in the blasting workshop are protected by galvanized bushings, and there are air switches and leakage protectors outside the workshop. The device and power switch adopt classic explosion-proof technology. It is forbidden to pull temporary lines without authorization. The circuit complies with industry standards.

Company leaders and employees regularly participate in safety education and training. The company conducts safety production education for the Dust explosion accident. Employees in dangerous positions must participate in safety education and training regularly. Employees in dangerous positions must receive special safety technology and business training. Only after passing the exam Induction.

Formulate corporate dust-proof facilities specifications and safety inspection forms, and safety management personnel will conduct dust-proof inspections every week and keep records.

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.