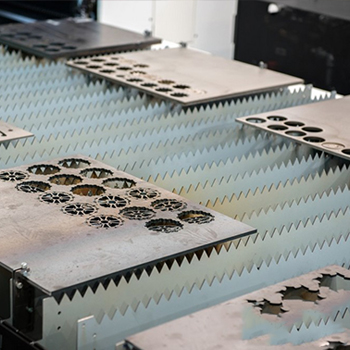

The working dust of the whole Explosion-proof vacuum cleaner should meet the following requirements:

The system should be integrated near the dust collection point in the unified production process.

For different types of dust, different dust mixing recycling methods can be used, or an independent recycling system can be established, without the need to invest in recycling costs.

For the large temperature and humidity changes and the dust that may be condensed by the mixed wind, the system should be installed separately.

When designing the dust removal system, the industrial Whole machine explosion-proof vacuum cleaner should seriously consider the following issues.

Do not have too many exhaust pipes, which can help balance the resistance of each branch. The branch pipe can be connected with a large section of collecting pipe when the discharge is excessive. The collection tube has a flow rate of 3 meters per second.

The pipes of the dust collection pipe system should be as vertical or inclined as possible to avoid accumulation of dust. The inclined pipe and the angle of inclination should be greater than 45 degrees. Once paved, it must be exported.

The dust collecting pipe generally adopts a small-diameter annular pipe with high wind speed. However, in order to prevent clogging, the diameter of the dust collecting pipe cannot be smaller than the following value.

The water quality treatment system requires a good hydraulic balance. Hydraulic calculations are applicable to parallel pipes. For the same total air system, the pressure difference between the two pipes must not exceed 15%, and the pressure difference between the two pipes must not exceed 10% to ensure that the air volume of each pipe meets the design requirements.

In addition to affecting the economy of the system, the wind speed of the ducts of the dust removal system should also consider factors such as equipment configuration and duct wear, duct dust, and duct blockage. In order to prevent dust and pipe blockage, the wind speed on the pipe should not be lower than the low air volume in the table below.

In actual work, the Industrial machine explosion-proof vacuum cleaner system should pay attention to the following matters.

In addition, in the workshop of a pharmaceutical factory, because the vacuum cleaner has many dust collection points, the dust collection time is long, and the dust collection capacity is large, which has a great impact on dust removal. Therefore, it is very necessary to set up a dust removal equipment adjustment room near the dust collection point.

If the conditions are limited, other methods can be used for recycling, such as a mobile sweeper or a direct recycling exhaust system, which can directly discharge the part that generates a small amount of dust outdoors.

In order to ensure the normal operation of the dust removal system and prevent secondary pollution, the principle of dust removal under the dust removal pipeline is to remove secondary pollution, purify step by step, and improve economic benefits.

According to indicators such as production technology, dust removal quality, recycling cost, dust collection volume, on-site recycling, and comprehensive waste treatment.

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.