In the field of smoke and dust control, pulse cartridge dust collector and

Filter cartridge dust removal equipment have high dust removal efficiency, will

not cause secondary pollution, and are easy to recycle dry materials. They are

more and more widely used at home and abroad, accounting for 80%. The metal

processing industry is one of the main sources of air pollution. Current market

situation my country has a huge demand for bag filter, and dust filter

materials, especially high temperature resistant fiber filter materials, have

broad market development prospects. .

Pulse cartridge dust collector and Filter cartridge dust removal equipment are widely used in various AC arc welding machines, DC welding machines, argon

arc welding machines, carbon dioxide shielded welding machines, butt welding

machines, spot welding machines, submerged arc welding machines, high frequency

Welding machine, flash butt welding machine, pressure welding machine, butt

welding machine, laser welding machine, AC welding machine and DC welding

machine, arc welding, CO2 shielded welding, MAG shielded welding, special

welding, gas melting cutting, etc. Treatment of flue gas generated during

welding and polishing of aluminum and other metals, and other chemicals. The

purification of smoke and dust generated in other processes, as well as the

recovery of rare metals and precious materials, are suitable for stations where

dust removal is relatively dispersed and the amount of smoke is large.

After the cyclone dust collector is installed with a bypass, its working

principle is that the dust-laden gas enters tangentially from the inlet. While

the airflow is rotating, the airflow separates up and down to form a double

spiral motion, and the dust is separated strongly at the boundary of the double

spiral. Function, the coarser dust particles are separated to the outer wall

with the downward spiral airflow, part of the dust is drawn out from the middle

opening of the bypass separation chamber, and the remaining dust is carried by

the downward airflow into the ash hopper.

The upward swirling airflow has a gathering effect on fine particles of

dust, thereby improving the efficiency of dust removal. This part of the finer

dust particles is carried upward by the upper spiral airflow, forming a strongly

rotating upper dust ring under the top cover, and enters the upper opening of

the bypass separation chamber together with the upper spiral airflow, and is

introduced into the cone through the air return port Converging with the

internal air flow, the purified gas is discharged from the exhaust pipe, and the

separated dust enters the hopper. The pulse cartridge dust collector and Filter

cartridge dust removal equipment systems are mainly composed of box assembly,

filter bag, cage assembly, pulse blowing system, ash discharge system, fan,

control system, etc. . Supporting equipment: purifier + activated carbon

adsorption tower. Project effect: The exhaust gas collected by the air

collecting hood is passed through the air duct to remove the particulate matter

in the exhaust gas, and then passes through the mist eliminator to reduce the

water vapor and then enters the next process. Cooperative photolysis and

oxidation of organic waste gas and odorous gas can degrade and convert odorous

gas substances into low-molecular compounds, water and carbon oxides, and meet

high-altitude emission standards.

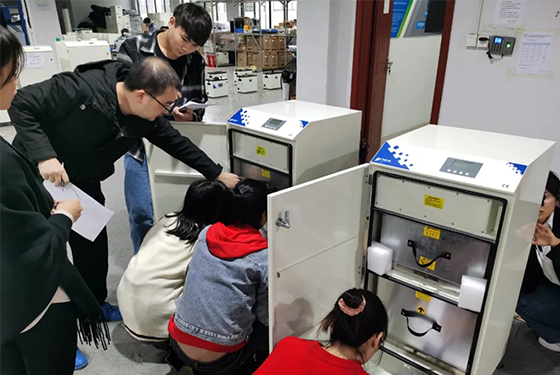

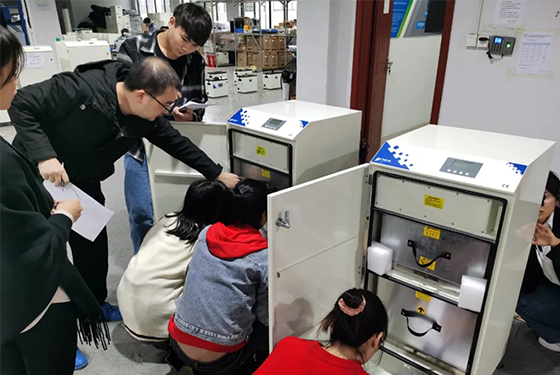

If you need to buy industry dust collector, please contact with ‘Dongguan

Pure-Air Tech Co.,Ltd.’.