The appearance of the Pure-Air food processing dust collector is

characterized by a box-type cabinet structure, a large fan air volume, and a

small footprint. It adopts an integrated chassis structure and has a simple and

elegant appearance. It is designed for carbon powder, graphite powder, cement

powder, flour, etc. Floating dust collection configuration with large amount of

dust is designed to perfectly integrate with the host.

Power system: use Siemens three-phase asynchronous motor, with three-phase

380V voltage, equipped with special customized aluminum alloy impeller of

PURE-AIR, excellent negative pressure and flow, smooth operation of the dust

collector, low failure rate, low noise, and 24 Work continuously and efficiently

within hours.

Electrical system: The main electronic control components adopt the

international famous brand-Schneider of France. Independent control of the

electric box, built-in AC contactor, thermal overload protection, phase sequence

protection such as phase loss and reverse phase, high safety. The control panel

is simple and clear, and can easily realize the remote linkage control

function.

Filter system: Using Japan Toray polyester fiber substrate, high-efficiency

PTFE membrane filter cartridge, high filtration accuracy. The standard

configuration is polyester fiber oil-proof and waterproof material, and the

filtration accuracy of dust with an equivalent diameter of 3 microns or more can

reach more than 99%. A higher filtration accuracy filter cartridge material can

be selected.

Self-developed dust removal technology: self-developed patented automatic

rotary pulse back-blowing technology, the cleaning effect is 3 times higher than

the traditional method, the pulse back-blowing system is composed of gas storage

tank, solenoid valve, pulse controller, automatic rotation injection components,

etc.

When the pulse controller sends out a pulse signal, the solenoid valve

starts to work. The high-pressure air sprayed out at a high flow rate enters the

inner wall of the filter cartridge through the automatic rotating blowing

assembly, causing the filter cartridge to expand sharply, causing shock and

vibration, so that the dust attached to the surface of the filter cartridge is

shaken off to the dust collecting drawer in.

Dust collection box: The drawer type dust collection box is practical and

convenient, in order to avoid manual cleaning of the outer surface of the filter

cartridge causing dust to splash around and form secondary pollution. The dust

box adopts a drawer type structure. When there is a lot of dust accumulation,

open the door, pull the dust box out to clean the dust, and then send the dust

box in after completion. Convenient, fast and practical.

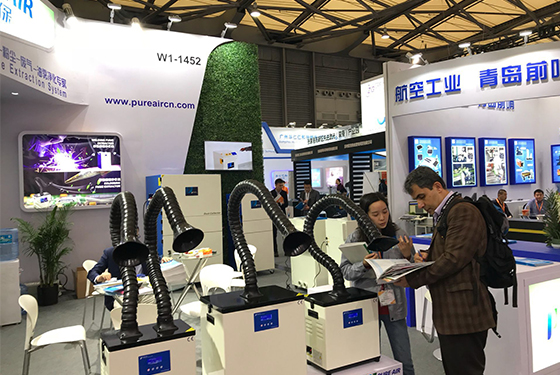

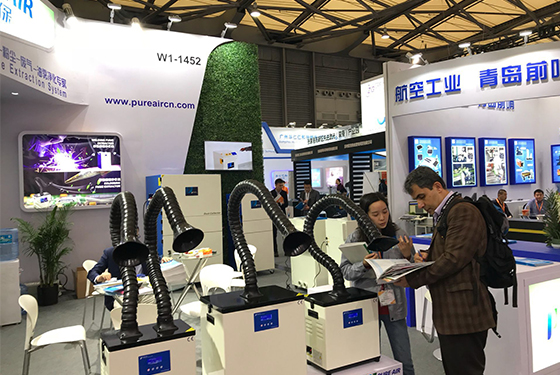

Universal suction arm: Built-in skeleton, can hover anywhere in 360

degrees. The smoking hood adopts a large-scale mask design, which can inhale the

welding fumes with maximum efficiency; the suction arm hose is made of

high-grade polyester material, which is fireproof and flame retardant. Optional

horseshoe shape, top hat shape, etc., or customized stainless steel

material.

Quality casters: industrial casters, non-slip and wear-resistant, easy to

move, easy to install. The wheels are made of top-grade polyurethane (PU), and

the bracket is made of 2.5mm pickling plates to increase the reinforcement. The

3-inch casters can carry 150kg individually, and the tread is designed to

enhance the anti-skid performance.

Dongguan Pure-Air Tech Co.,Ltd as a manufacturer of dust collectors for

more than 10 years, has made a lot of achievements in the field of dust

collectors and has become a long-term supporting partner of Fortune 500

companies.