Dongguan Pure-Air Tech Co.,Ltd. specializes in manufacturing indoor dust

purifiers & laser air clean equipment and many other smoke and dust

purification equipment!

When employees of an enterprise work in a dusty natural environment in the

workshop, the key deficiencies of the production line in the abrasives field at

this stage are:

1. In my country's abrasives manufacturing companies, it is common to see

unreasonable processing technology, production layout and freight logistics. The

specific manifestation is that there are too many cars going back and forth and

frequent transportation. The raw materials are often scattered due to several

transportations, resulting in dust. Times flying. In addition, there is usually

no management method for the accumulation of raw materials. Most of the

abrasives (steel jade and carbon-carbon composite materials) are immediately

stored on the road surface. Due to the weather, dust on the construction site

often occurs, which not only causes damage to the raw materials and air

pollution. In addition, it also endangers product quality.

2. Due to the divergence between the sealing of machinery and equipment and

the actual operation, the airtight cover is often destroyed, and the software

characteristics of the ventilation and dust removal system cannot be guaranteed.

Environmental pollution caused by dust on the manufacturing site is relatively

serious. Its dust removal equipment is damaged, the abrasive strength is very

high, and the hardness is above 9.0, resulting in serious damage to the metal

structure of the dust collector, ventilation duct, centrifugal fan and its bag

filter.

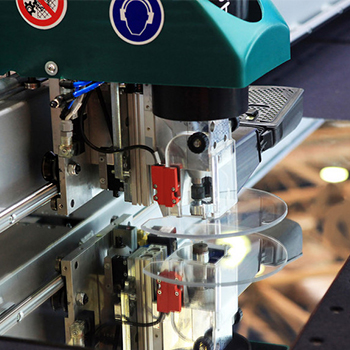

Fully equipped to deal with dust

3. One of the key processing techniques in steel production is to mix raw

materials according to a certain proportion and convert them into small

abrasives in the smelter in the intermediate frequency furnace, which causes a

lot of dust in the whole process of the smelter. In order to facilitate feeding

and picking, most companies choose semi-closed covers. The problem caused by the

semi-closed hood is the large amount of smoke and dust, and the second is the

large amount of steam flowing into the hood caused by the circulating water of

the furnace skin cooling. These two problems have caused great difficulties in

the purification treatment of smoke and dust, and many manufacturing enterprises

have not adopted the purification treatment countermeasures. Environmental

pollution is very serious.

4. The dust collector used in the abrasives field is dominant. Because of

the error in understanding the dust characteristics or insufficient project

investment, many dust collector equipment cannot meet the standard, and the

initial project investment of the central ventilation and dust removal project

is relatively high.

If you want to buy a dust collector for workshop, please contact with ‘Dongguan Pure-Air Tech Co.,Ltd.’.