At present, environmental pollution in industrial production workshops is a key link in environmental protection. During the rapid development of heavy industry, environmental pollution will affect my country’s air environment indiscriminately. Therefore, the country must pay attention to the dust, smoke, exhaust gas, etc. generated in the workshop. As long as it does not meet the national or local standards, it must be treated. The environmental protection department does not agree. This article first introduces the treatment of welding fume in electric welding workshops, using Fixed welding fume purifier.

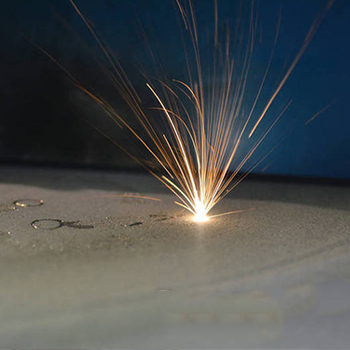

The fume and exhaust gas generated by the welder is generally composed of fume and dust, and it is necessary to filter large particles of sparks and small dust during processing. Because the smoke and dust produced during the welding process in the workshop are more harmful, the harm of nitrogen oxides to the human body is mainly the impact on the lung tissue. After being inhaled into the respiratory tract, nitrate and nitrite are formed in the alveoli, which can cause various hazards to the lung tissue. It is strongly recommended to use a fixed Welding fume purifier!

Stationary welding fume purifier: Under the action of high negative pressure of the equipment, it enters the inside of the purifier through the air inlet pipe. Before entering the clean room, the welding, cutting, and grinding fume with sparks is isolated by the flame-retardant screen frame, and the welding, cutting, and grinding fume at the remaining temperature is evenly distributed to the pressure vessel of the clean room through the baffle, which is better Filter cartridge purification. Under the action of gravity, large particles of smoke and dust sink into the dust collecting hopper, and the floating dust of small particles generates a vortex under the action of suction, and the purification room needs filter cartridge filtration. After collection and combination, the small particles of dust adsorbed on the surface of the filter cartridge fall under the action of gravity, sink into the dust bucket, and the purified air flow is discharged to the workers in a healthy working environment.

Activity Fume treatment equipment: During the production process, the fume generated by the gravity of the fan is sucked into the movable fume purifier through the suction hood. First, the secondary fire barrier at the air inlet of the purifier separates and cuts large particles from the spark particles produced by grinding. The preliminarily filtered smoke and dust pass through the filter element protection plate to further prevent the entry of spark residues. The filtered smoke and dust enter the main filter element. The main filter element is made of imported anti-static film polyester fiber material, with a filtration rate of 99.97%. The purified gas is further purified by activated carbon filter cotton and then discharged qualified.

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.