Strictly control fire sources; fire hydrants are the most practical and effective dust-proof and explosion-proof measures. Electric sparks, static sparks, friction sparks, open flames, high-temperature object surfaces and welding and cutting sparks are the main factors that cause dust explosions in ordinary burners. Therefore, this point is worth paying attention to. Electrical equipment should be designed and installed in strict accordance with the requirements of the "Code for Design of Electrical Installations in Explosive and Fire Hazardous Environments" to meet the requirements of full explosion protection. Avoid installing or installing mechanical equipment that is prone to static electricity and sparks. The abrasive must be strictly screened. After removing the stone and iron, so as to prevent the impurities from entering the grinder to produce sparks. Workshop dust explosion-proof vacuum cleaner.

If it is a small crushing equipment, its strength can be improved, and it should be considered to prevent the explosion flame from spreading through the stitches. In order to reduce the destructiveness of the explosion, a pressure release device can be installed, such as a light roof, wall, or heightened doors and windows in the factory building. However, it should be noted that the pressure reducing device is best to be close to explosive places, not towards places with high traffic and traffic arteries; in order to reduce the content of combustion-supporting gas, inert gas (such as nitrogen) should be added to the mixture of dust and combustion-supporting gas , To reduce the oxygen content. Dust explosion-proof vacuum cleaner in the workshop.

Strict safety production management. Strengthen safety education and training, strengthen safety inspections, eliminate safety hazards, improve safety production rules and regulations, and strictly pursue accountability.

Due to the special nature of dust explosions, the dust removal method for dust explosions is also different from general fire explosions. The focus is on avoiding the formation of suspended dust: workshop dust Explosion-proof vacuum cleaner.

During the fire fighting process, the formation of suspended matter and sediment dust should be avoided as much as possible to avoid explosion, and the suspended matter may explode. Therefore, fighting dust fires should be paid attention to. The common treatment measures are to avoid the use of powerful compression-ignition fire extinguishers or the use of water to extinguish fires at the dust fire site. DC water guns are not suitable for use, but nozzles or fireworks should be used to extinguish fires.

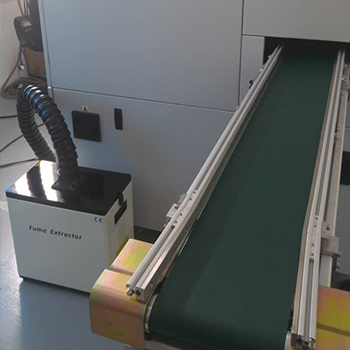

If you want buy fume extractor, please contact with Dongguan Pure-Air Tech Co.,ltd, E-mail: sales@pure-airtech.com.